WAFO bimetallic cylinders for the highest demands

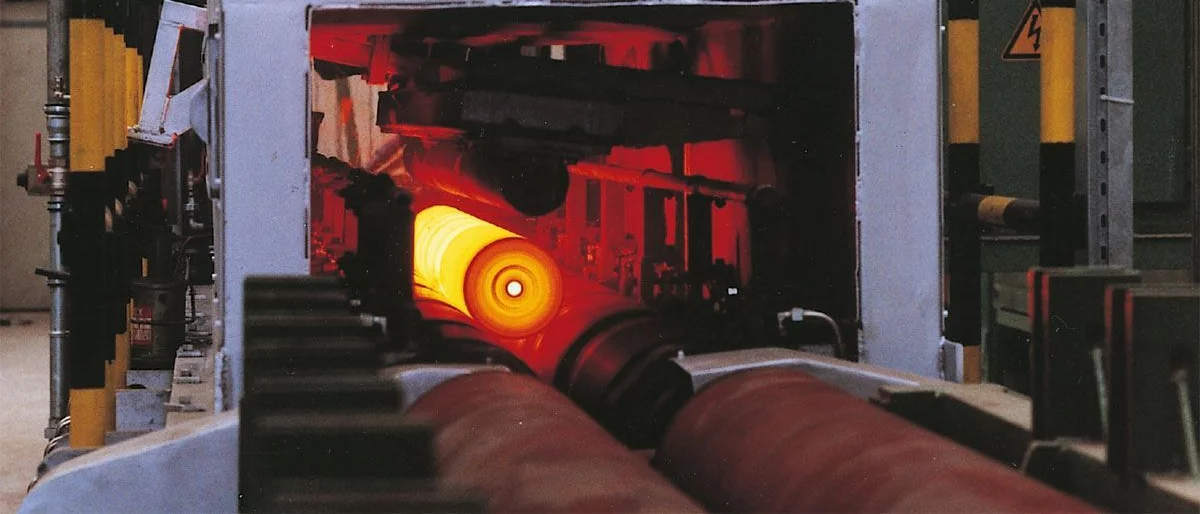

WAFO has developed a process-controlled bimetal centrifugal system in co-operation with various technology providers.

By using a tried-and-tested line inductor, a carrier tube is gently heated and then set to a high rotational speed in a second stage. This so-called centrifugal spinning causes the hard material alloy to bond homogeneously with the carrier tube in a diffusion zone. In conjunction with a sophisticated process technology, a low-stress end product is created with uniform properties in both the inner cladding and the carrier material.

Bimetallic cylinder

Various centrifugal alloys have been developed in accordance with the operating and application conditions. The carrier materials were predetermined with a safety factor of 1.2 in relation to the cylinder strength and the hot yield strength.

| Three groups of materials are available for the armouring | |||

|---|---|---|---|

| WA-5 | WA-5.5 | WA-77 | WA-880 |

| Fe-Ni-B | Ni-Co | Fe-Cr-Ni-B | Ni-Cr-WC-CO |

| Abrasion resistant | Corrosion resistant | Corrosion and abrasion resistant | Highly resistant to abrasion and corrosion |

| 60-65 HRC (300° C) | 55 - 58 HRC (300° C) | 56-63 HRC (300° C) | 52-58 HRC (300° C) |

We manufacture parallel and conical twin-screw barrels in wear-protected design

WAFO specialises in wear-protected barrels for conical twin-screw extruders.

We use a special material that has been found in a large number of tests to manufacture the conical, wear-protected barrels, which are usually divided into three segments. After mechanical processing, we treat the cylinder segments in a diffusion hardening process that is virtually distortion-free.

We have modified this process and the combination of suitable material and heat treatment process with our expertise in such a way that optimum conditions are achieved.

For optimum service life, even with conical twin-screw extruders:

The wear-resistant design from WAFO

This gives you a twin-screw cylinder that achieves around twice the service life of a nitrided cylinder, but costs only 15 to 20 per cent more. This means that cost-effectiveness is no longer a question at the time of purchase.

An additional advantage is the extended service life. With the wear-protected barrel, you can operate your extruder at nominal output for longer without any wear-related loss of throughput. This reduces your production costs and improves your competitiveness.

We can also manufacture parallel twin-screw barrels with highly wear-resistant twin bushes made from our tried-and-tested bimetal. We have the right bimetal in our portfolio for every special application.