We regenerate worn screws and cylinders

Screws or barrels that have reached their wear limit belong in the hands of WAFO. We have 25 years of experience in the regeneration of wearing parts.

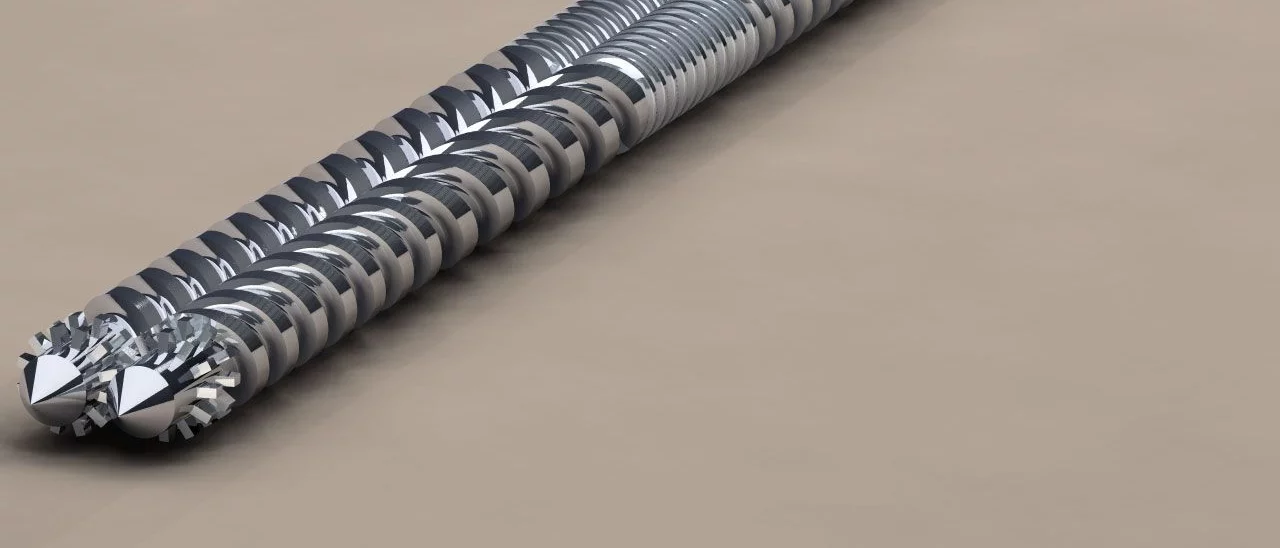

We first remove the worn base material from the screws. Then we create new screw flights by build-up welding a special, highly wear-resistant armour alloy. For special cases, the base and flanks of the worm can also be hard-faced. Subsequent straightening, grinding and polishing gives the screw its final geometry. It is therefore better protected against wear than standard, new, nitrided screws.

Hardfacing is usually cheaper than a new screw. And - a decisive plus is the improved service life.

If the screw and barrel are regenerated at the same time, cylinders made of nitriding steel can usually be honed and then intensively nitrided.

We take the increased cylinder diameter resulting from the honing process into account when regenerating the screw; the screw and cylinder fit together again afterwards.

We drill out the worn barrel to remove the bushing. Using a process developed by us, we insert a wear-resistant bushing that is fixed and torsion-proof. The cylinder is restored to its original diameter and you can use a screw with the original diameter as before.

The material available for the bushing is either chrome steel, particularly wear-resistant and corrosion-resistant powder metallurgical materials or bimetals.

Special hardfacing for rubber extruders

In a large number of cases, hard facing with conventional coating materials, such as stellite, has not proved successful.

During rubber processing, a very high surface pressure occurs between the screw flight and the barrel wall. This is caused by unequal force balances when the usually only slightly pre-tempered rubber strips are drawn in.

The resulting compressive stress, also known as sigma stress, far exceeds the limits of stellite.

Sometimes an armoured screw with stellite has only half the service life of a normal nitrided screw.

For this reason, we use a nitrided armour material.

This material already has a basic hardness of approx. 50 HRC after welding and is then nitrided.

The support effect resulting from the high base hardness in relation to the nitrided layer significantly improves the wear behaviour compared to normally nitrided screws.

WAFO system technology

Screw regeneration in 4 weeks

- Reproducible armouring with PTA welding machines

- Multi-layer system armouring

- High level of automation in production

- Collection and delivery by our own lorries

- Decommissioning of your machine at the agreed time, therefore no replacement set necessary

- Free wear and material analyses

- Comprehensive customer support

WAFO's answer to screw wear

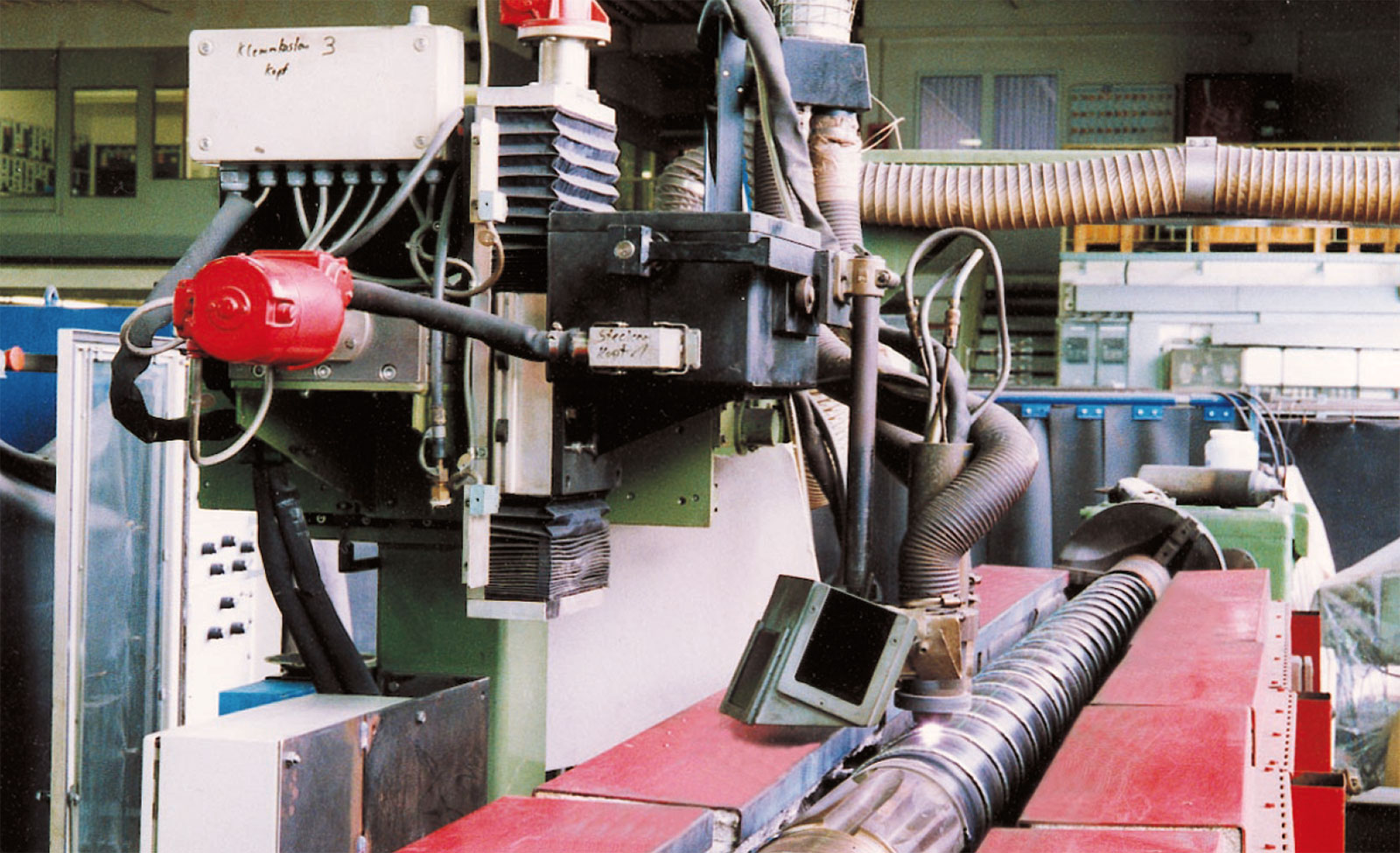

Since 1997, we have had a modern screw service centre at our disposal to enable us to regenerate screws with increased value through wear-resistant web armouring in the shortest possible processing time.

We use a CNC-controlled plasma powder welding system (PTA) of the latest generation for the welding process. The process enables high-quality and reproducible web, flank and solid armouring.

The mechanical processing to new worm condition is carried out on machines, some of which we developed ourselves.

| Characteristics | Material type | ||||

|---|---|---|---|---|---|

| Stellit 6 | Stellit 12 | Stellit 1 | Colmonoy 56 | WP 88 | |

| Alloy | Co-Cr-W | Co-Cr-W | Co-Cr-W | Ni-Cr | NiCr+WC |

| Hardness of the armour HRC | 38-42 | 43-49 | 48-55 | 48-53 | 56-60 |

| Wear resistance | ✪✪ | ✪✪✪ | ✪✪✪ | ✪✪✪ | ✪✪✪✪ |

| Corrosion resistance | ✪ | ✪✪✪ | ✪✪ | ✪✪✪✪ | ✪✪✪✪ |

| Relative wear during assembly | ||||||

|---|---|---|---|---|---|---|

| Screw | Stellit 6 | Stellit 12 | Stellit 1 | Colmonoy 56 | Colmonoy 56 | WP 88 |

| Cylinder | WA5 | WA5 | WA5 | WA77 | WA880 | WA880 |

| Screw | ✪✪✪✪ | ✪✪✪ | ✪✪✪ | ✪✪ | ✪✪✪ | ✪✪ |

| Cylinder | ✪ | ✪✪ | ✪✪ | ✪✪ | ✪ | ✪ |

Other armour materials and special surfaces on request!

Stellite® is a trademark of Deloro Stellite Holdings Corporation.

The bar armouring first used by WAFO as a pioneer 30 years ago has become established worldwide over the years.

The materials we use, Stellite, have proven themselves in thousands of WAFO reconditioned screws.

But nothing is so good that it cannot be improved. Our answer to this challenge is WT 50, an armour material that produces even better results in special cases. WT 50 is an armour material specially adapted by WAFO. Special armouring

This material consists of a very hard and therefore very wear-resistant intermetallic compound, which is embedded in a soft nickel matrix. This alloy is characterised by excellent sliding properties and very good corrosion and wear resistance over a wide temperature range.

The hardness is around 50 HRC. We also use our armour material WT 60 as a supplement to this.

This is a cobalt-based material with the same properties as our WT 50, but with a hardness of approx. 58 HRC.

Thanks to a special plasma welding system, we are able to apply highly wear-resistant armouring with a Ni-Cr matrix and a high proportion of extremely hard tungsten carbides to screws.